Here are some examples of cuts in both clear plastic and polyimide using a variety of laser types.

In the following figures, "A" shows clear plastic, while "B" shows polyimide.

Figure 1A Figure 1A |

Figure 1B Figure 1B |

Figure 1 shows the 1.5 W, 355 nm laser results. Both cuts are relatively clean with a small heat affected zone (HAZ). It took about one minute to make a complete part. |

Figure 2A Figure 2A |

Figure 2B Figure 2B |

Figure 2 shows the 3.0 W, 355 nm laser results. A slightly higher HAZ, but still decent quality. These parts took about 18 seconds to process at double the power of the previous. |

Figure 3A Figure 3A |

Figure 3B Figure 3B |

Figure 3 shows the 1.5 W, 266 nm laser results. With one of the best cut qualities, this one still took the least time of the tested UV lasers, 12 seconds. |

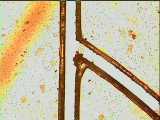

Figure 4A Figure 4A |

Figure 4B Figure 4B |

Figure 4 shows the broadband RF CO₂ laser. It took only about 400 ms to make the cut, but it's pretty poor quality with a large HAZ. |

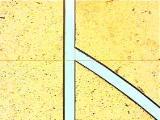

Figure 5A Figure 5A |

Figure 5B Figure 5B |

Figure 5 shows the 9 μm RF CO₂ laser. Still can't compete with the UV lasers. This also took about 400 ms. |

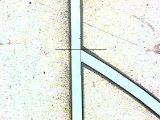

Figure 6A Figure 6A |

Figure 6B Figure 6B |

Figure 6 shows the results of a line-narrowed CO₂-T laser. Good cut quality, nice thin line. |

Figure 7A Figure 7A |

Figure 7B Figure 7B |

Figure 7 shows Q-switched CO₂ results. The process speed was about 700 ms and produced results comparable to the UV lasers. |

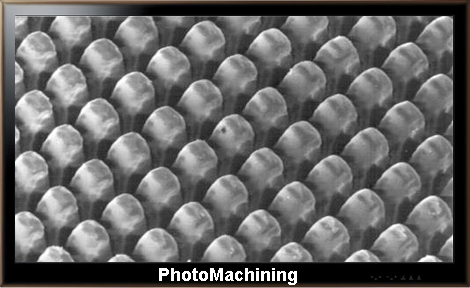

Figure 8A Figure 8A |

Figure 8B Figure 8B |

Figure 8 shows cuts made with a 248 nm KrF Excimer laser. The process took hours, not seconds, but not the exceptional edge quality. |

Figure 9A Figure 9A |

Figure 9B Figure 9B |

Figure 9 shows cuts made with a 355 nm, 12 ps laser. |

Figure 10A Figure 10A |

Figure 10B Figure 10B |

Figure 10 shows cuts made with a 532 nm, 12 ps laser. |

Figure 11A Figure 11A |

Figure 11B Figure 11B |

Figure 11 shows cuts made with a 1064 nm, 12 ps laser. |

|

Figure 1A

Figure 1A Figure 1B

Figure 1B Figure 2A

Figure 2A Figure 2B

Figure 2B Figure 3A

Figure 3A Figure 3B

Figure 3B Figure 4A

Figure 4A Figure 4B

Figure 4B Figure 5A

Figure 5A Figure 5B

Figure 5B Figure 6A

Figure 6A Figure 6B

Figure 6B Figure 7A

Figure 7A Figure 7B

Figure 7B Figure 8A

Figure 8A Figure 8B

Figure 8B Figure 9A

Figure 9A Figure 9B

Figure 9B Figure 10A

Figure 10A Figure 10B

Figure 10B Figure 11A

Figure 11A Figure 11B

Figure 11B